If you’re looking for the best braided brake lines for safer, smarter stopping, I recommend options like all-metal braided stainless steel hoses with PTFE lining, known for durability, flexibility, and resistance to high pressure. Quality fittings, corrosion resistance, and proper length are essential for ultimate performance. Whether for off-road, lifted trucks, or racing, these lines improve pedal firmness and responsiveness. If you’d like to discover which options best suit your vehicle and needs, there’s more to explore below.

Key Takeaways

- High-quality braided stainless steel lines improve brake response and pedal firmness by reducing fluid expansion under pressure.

- Compatibility with various vehicle models and fittings ensures safe, custom-fit installation for enhanced braking performance.

- Durable construction with corrosion-resistant coatings extends lifespan and maintains safety in demanding environments.

- Different bend options (straight, 45°, 90°) support flexible routing and reliable connections for safer, efficient braking systems.

- Brands offering lifetime warranties and tested performance deliver confidence in safer, smarter stopping in all conditions.

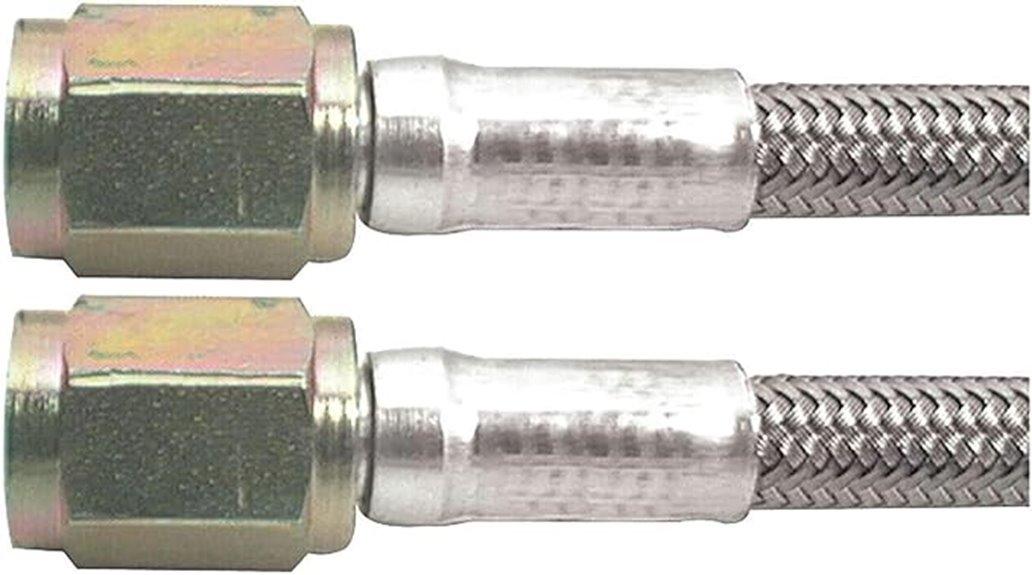

Allstar 18-inch Braided Stainless AN Hose Assembly

The Allstar 18-inch Braided Stainless AN Hose Assembly is an excellent choice for automotive enthusiasts and professionals seeking durable, high-performance brake or hydraulic lines. Its braided stainless steel construction with PTFE lining guarantees strength, flexibility, and resistance to high pressures. The assembly features 3 AN straight female fittings on both ends, making it versatile for various vehicle setups. Weighing just 1.76 ounces, it’s lightweight yet rugged, with a multi-color exterior for a sleek look. Ideal for brake lines, clutch systems, and racing applications, this hose offers reliable, long-term performance and a secure fit in complex systems.

Best For: automotive enthusiasts and professionals needing durable, high-performance brake or hydraulic lines for racing, motorcycle, or custom vehicle applications.

Pros:

- High-quality braided stainless steel construction with PTFE lining for strength and flexibility

- Versatile with 3 AN straight female fittings on each end, suitable for various vehicle setups

- Lightweight at 1.76 ounces, providing durability without adding significant weight

Cons:

- Labels indicating “Off Road Use Only” may cause confusion about primary applications

- Limited to 18-inch length, which may not suit all installation needs

- May require compatible fittings or adapters for specific vehicle configurations

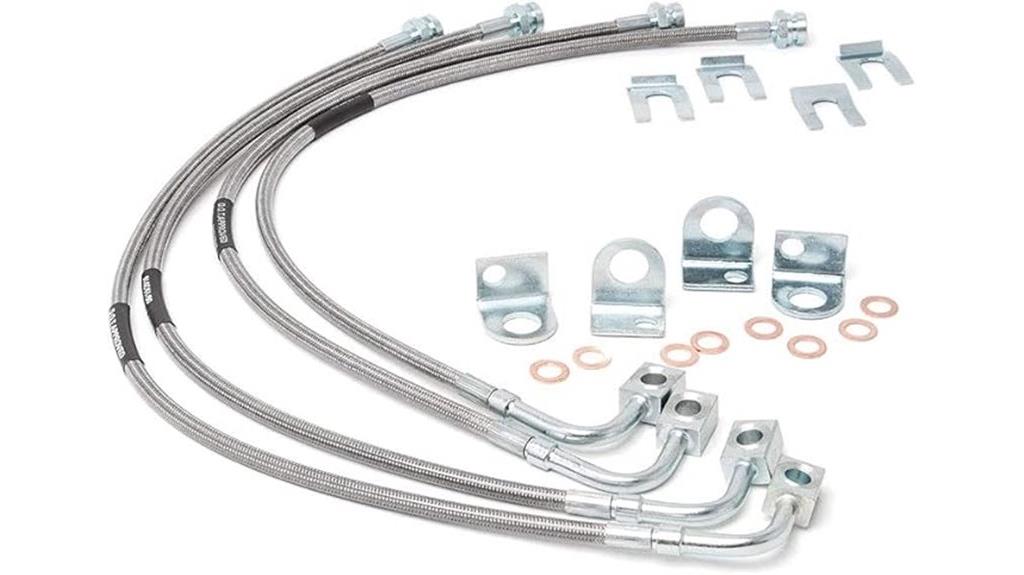

Rough Country Stainless Brake Lines for Jeep Wrangler JK (2007-2018)

If you own a Jeep Wrangler JK with a 4-6 inch lift and want to improve your braking performance and durability, Rough Country Stainless Brake Lines are an excellent choice. Designed specifically for 2007-2018 models, they feature stainless steel construction with braided shields that resist off-road debris, mud, and rocks. These lines are DOT approved, ensuring safety compliance, and include high-quality fasteners for a leak-free connection. The extra length makes installation easier and enhances braking response. Compared to factory rubber lines, these offer greater durability, longevity, and resistance to environmental damage, backed by Rough Country’s lifetime replacement guarantee for reliable, long-term use.

Best For: Jeep Wrangler JK owners with 4-6 inch lifts seeking enhanced brake durability, performance, and off-road protection.

Pros:

- Made of stainless steel with braided shielding for superior resistance to debris and environmental damage

- DOT approved to meet safety standards and ensure reliable braking performance

- Longer length and high-quality fasteners facilitate easier installation and leak-free operation

Cons:

- May be more expensive than standard rubber brake lines

- Installation may require some mechanical knowledge and tools for proper fitment

- Not compatible with Jeep models outside the 2007-2018 JK range or with lifts outside 4-6 inches

Allstar Performance 12 Coated Braided Brake Line (ALL48361)

For anyone upgrading or replacing brake lines in their vehicle, the Allstar Performance 12 Coated Braided Brake Line (ALL48361) stands out as a reliable choice. Its 12-inch stainless steel braided design with black vinyl coating offers durability and corrosion resistance. The PTFE lining guarantees high performance under extreme pressure and heat, making it ideal for both daily driving and racing. With straight female fittings and a 3 AN size, installation is straightforward. Customers praise its quality, professional appearance, and leak prevention. Made in the USA, it combines durability with a sleek look, offering excellent value for anyone seeking a dependable brake line upgrade.

Best For: automotive enthusiasts and professionals seeking durable, high-performance brake lines for upgrades, replacements, or racing applications.

Pros:

- Constructed with stainless steel braided and PTFE lining for superior durability and heat resistance

- Black vinyl coating provides corrosion protection and a sleek appearance

- Easy to install with straight female fittings and 3 AN size design

Cons:

- Slightly more expensive than basic rubber brake lines

- Length is fixed at 12 inches, which may not suit all vehicle configurations

- Requires proper fitting and installation knowledge to ensure safety and performance

Allstar Performance ALL46302-60 60 #3 Braided Steel Lines With -3 Ends

Allstar Performance ALL46302-60 stands out as a top choice for enthusiasts seeking durable and flexible braided brake lines, especially those working on high-performance or racing vehicles. This 5-foot line features stainless steel construction with a PTFE lining compatible with all brake fluids, ensuring reliable performance. The -3 AN ends include one straight fitting, with options for 45° or 90° on the other side, providing versatility. Its abrasion-resistant outer layer and corrosion resistance make it ideal for demanding environments. Rated 4.6 out of 5 stars, users praise its fit and quality, though some report threading issues. Overall, it’s a solid, high-quality option for safer, smarter stopping.

Best For: enthusiasts and professionals seeking durable, flexible braided steel brake lines for high-performance or racing vehicles that require reliable, corrosion-resistant performance.

Pros:

- Made from high-quality stainless steel with PTFE lining for excellent compatibility with all brake fluids

- Offers superior durability, flexibility, and abrasion resistance suitable for demanding environments

- Includes versatile -3 AN fittings with options for straight, 45°, or 90° connections

Cons:

- Some users have experienced threading issues or fitting breakage during installation

- May require careful inspection and proper installation to prevent leaks or damage

- Mixed reviews regarding long-term durability, with a few reports of breakage or fitting problems

Rough Country GM Front Brake Lines for 2007-2019 1500/11-19 2500/3500HD

Rough Country GM Front Brake Lines are an excellent choice for lifted trucks needing longer, durable brake hoses. They’re designed specifically for 2007-2019 Silverado 1500, 2500HD, and 3500HD models with lifts of 5-7.5 inches. Made from stainless steel braided material, these lines resist corrosion and expansion, supporting up to 4000 PSI. Installation is straightforward using factory clips, and they improve brake response and flexibility over stock rubber lines. Although some fitment issues exist with certain models, overall users praise their durability, performance, and quality. Backed by a lifetime warranty, they’re a reliable upgrade for lifted trucks seeking safer, smarter stopping power.

Best For: lifted Silverado 1500, 2500HD, and 3500HD owners needing durable, longer front brake lines for improved performance and safety on lifts of 5-7.5 inches.

Pros:

- Made from high-quality stainless steel braided material for corrosion resistance and durability.

- Supports up to 4000 PSI, ensuring reliable high-pressure performance.

- Easy installation using factory clips with noticeable improvements in brake response and flexibility.

Cons:

- Some fitment issues reported with specific models like 2007 Silverado 2500HD Classic.

- Lines are not labeled for driver/passenger sides, requiring measurement and testing before installation.

- Slightly smaller diameter than stock lines may require crimping or adjustments during installation.

Allstar Performance ALL46400-18 18 4 AN Braided Brake Line

The Allstar Performance ALL46400-18 braided brake line stands out as an excellent choice for enthusiasts seeking a durable and flexible upgrade. Its 18-inch braided stainless steel exterior combined with a PTFE lining offers exceptional resistance to abrasion and corrosion, making it ideal for high-flex environments. The line features versatile fittings—one straight end and options for straight, 45°, or 90° on the other—ensuring a custom fit. Weighing just 2.82 ounces, it’s lightweight yet robust. Customers praise its bendability, quality braiding, and reliable performance across brake, clutch, and sensor applications, making it a versatile upgrade for improved safety and longevity.

Best For: automotive enthusiasts and mechanics seeking a durable, flexible, and high-performance braided brake line for brake, clutch, or sensor applications.

Pros:

- Highly resistant to abrasion and corrosion due to braided stainless steel exterior and PTFE lining

- Flexible and easy to bend, making installation straightforward in custom setups

- Versatile fittings (straight, 45°, or 90°) allow for a precise fit and adaptable configurations

Cons:

- Requires thread sealant or tape on threaded ends for leak prevention

- May need adapters for certain fittings or sensor extensions in hydraulic systems

- Slightly higher cost compared to standard rubber hoses

StopTech 950.44007 Stainless Steel Braided Brake Hose Kit Front

If you’re looking to upgrade your vehicle’s braking system with a reliable and durable solution, the StopTech 950.44007 Stainless Steel Braided Brake Hose Kit (Front) is an excellent choice. It enhances braking performance by providing consistent pressure, a firmer pedal response, and improved feel. Made with a PTFE inner line, stainless steel braided cover, and abrasion-resistant PVC coating, it’s built to last. Designed specifically for models like the 3rd gen 4Runner and 1st gen Tacoma, it fits perfectly with OEM parts. Installation is straightforward, and users report noticeable improvements in responsiveness, making it a smart upgrade for safer, more confident stopping.

Best For: enthusiasts and vehicle owners seeking a durable, high-performance upgrade to their braking system, especially for 3rd gen 4Runner and 1st gen Tacoma models.

Pros:

- Improves braking response with consistent pressure and firmer pedal feel

- Made with durable PTFE inner line, stainless steel braid, and abrasion-resistant PVC coating for longevity

- Easy installation with OEM compatibility and included brackets and fittings

Cons:

- Shorter length than OEM hoses by about an inch, which may affect fitment in some setups

- Some customers experienced difficulty with customer support and warranty claims

- Slightly higher cost compared to rubber OEM hoses

Allstar Performance Stainless Steel Brake Hose Kit for GM Vehicles

Designed specifically for GM vehicles with metric brake systems, the Allstar Performance Stainless Steel Brake Hose Kit offers a reliable upgrade for brake conversions, replacements, or performance improvements. It fits models like GM G-Body, Camaro, Trans Am, and others, supporting 10mm to 1.5-inch bolts and larger applications with 7/16-20 bolts. The kit includes two 16-inch stainless braided lines, banjo fittings, bolts, crush washers, and mounting clips, all DOT approved and built for durability. Easy to install, this kit enhances brake system flexibility, reduces stress during heavy braking, and improves overall safety—making it a popular choice for both enthusiasts and daily drivers.

Best For: enthusiasts and mechanics seeking a durable, high-performance stainless steel brake hose upgrade for GM vehicles, including brake conversions and replacements.

Pros:

- Made from durable stainless steel with DOT approval for safety and longevity

- Easy to install with comprehensive hardware and fittings included

- Improves brake system flexibility, reducing stress and enhancing safety during heavy braking

Cons:

- May require verification of banjo bolt sizes for specific vehicle models

- Slightly more expensive than rubber brake lines

- Length may not be suitable for custom or non-standard brake setups

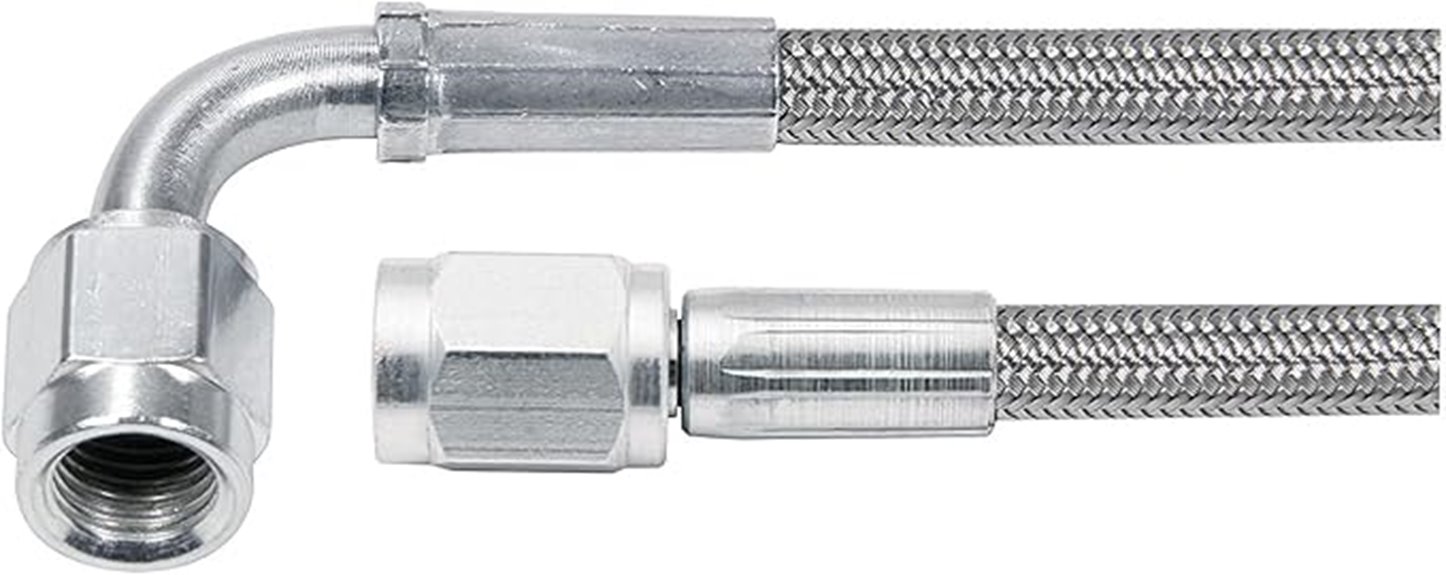

Allstar Performance 24-Inch AN Hose Assembly

For anyone looking to upgrade their vehicle’s fluid transfer system, the Allstar Performance 24-Inch AN Hose Assembly offers a reliable and versatile option. This 24-inch braided stainless steel hose features a PTFE lining, making it resistant to chemicals and high temperatures. It comes with a straight female fitting and a 90-degree female fitting, perfect for custom or replacement fluid lines in brake, hydraulic, or turbo oil systems. Made in the USA, it’s praised for ease of installation and durability, though some users have reported issues with crimped ends. Overall, it’s a solid choice for high-performance automotive applications.

Best For: Automotive enthusiasts and professionals seeking durable, high-performance fluid transfer lines for brake, hydraulic, or turbo oil systems.

Pros:

- Made in the USA with high-quality materials including braided stainless steel and PTFE lining for durability and chemical resistance

- Easy to install with included 3 AN fittings, suitable for custom or replacement applications

- Versatile for various high-performance automotive systems such as brakes, hydraulics, and turbo oil feeds

Cons:

- Some users have reported crimped ends falling off during installation, making the hose unusable

- Slightly higher cost compared to generic hoses due to premium materials and construction

- Limited length options, primarily available in 24 inches, which may not suit all installation needs

Russell Brake Line Kit (Stainless Steel) for GM HD Trucks

The Russell Brake Line Kit (Stainless Steel) for GM HD Trucks stands out as an excellent choice for truck owners seeking durability and reliable braking performance. Made from stainless steel with a braided design, this kit offers superior strength and resistance to wear. The zinc-plated fittings help prevent corrosion, ensuring long-lasting use. Designed specifically for 2001-2006 GM HD trucks, it enhances brake feel and responsiveness. Manufactured in the United States, this kit provides confidence during heavy-duty stops. Installation is straightforward, making it a reliable upgrade for those looking to improve safety and braking efficiency on their trucks.

Best For: truck owners with 2001-2006 GM HD trucks seeking a durable, corrosion-resistant brake line upgrade to enhance braking performance and safety.

Pros:

- Made from high-quality stainless steel for superior durability and wear resistance

- Braided design increases strength and flexibility for reliable performance

- Zinc-plated fittings resist corrosion, extending the lifespan of the brake lines

Cons:

- Installation may require some mechanical knowledge or professional assistance

- Stainless steel lines can be more rigid, making installation slightly more challenging

- Higher cost compared to standard rubber brake lines

Allstar Performance Brake Hose, 6 in Long, 3 AN Female to 3 AN 90° Female, Braided Stainless, PTFE Lined

If you’re seeking a durable and flexible brake line that can handle tight bends and high-performance conditions, the Allstar Performance Brake Hose is an excellent choice. It’s 6 inches long with 3 AN female fittings on both ends, including a 90° fitting for easier routing. The braided stainless steel exterior resists abrasion and corrosion, making it more durable than rubber hoses. Its PTFE lining is compatible with all brake fluids, ensuring reliable performance. Despite some customer feedback about crimping issues, this hose offers a sturdy, flexible solution for demanding applications. Overall, it’s a solid option for enhancing your brake system’s safety and efficiency.

Best For: automotive enthusiasts and professional mechanics seeking a durable, flexible brake hose for high-performance and tight routing applications.

Pros:

- Braided stainless steel exterior offers excellent resistance to abrasion and corrosion

- PTFE lining compatible with all brake fluids ensures versatile and reliable performance

- 90° fitting facilitates easier routing in confined spaces

Cons:

- Reports of crimping issues leading to fittings pulling off or difficulty reinstalling

- Ends not always properly crimped, affecting durability and safety

- Only one hose received despite multiple purchases, indicating potential packaging or fulfillment issues

The Stop Shop Universal Rear Braided Stainless Brake Hose

Designed for versatility, the Stop Shop Universal Rear Braided Stainless Brake Hose appeals to DIY enthusiasts and mechanics seeking a reliable upgrade for various vehicle rear brake systems. Made in the USA, this 21-inch stainless steel hose features a silver finish and includes fittings for different line sizes, such as 3/16 and 1/4 inch. Its durable construction and precise dimensions guarantee proper fitment on trucks like Ford F100, classic cars like the 1968 C10, and more. Rated 4.8 stars from 230 reviews, users praise its quality, ease of installation, and ability to improve brake performance by replacing old hard lines and reducing leak points.

Best For: DIY enthusiasts, mechanics, and vehicle owners seeking a durable, versatile upgrade for rear brake systems on trucks and classic cars.

Pros:

- Made in the USA with high-quality stainless steel construction for durability

- Includes fittings adaptable to various line sizes like 3/16 and 1/4 inch

- Easy to install and a reliable replacement for factory hard lines, reducing leak points

Cons:

- Not vehicle-specific; users must verify compatibility and dimensions before installation

- May require additional fittings or adapters depending on vehicle setup

- Limited to rear brake applications; not suitable for front or other brake system parts

Factors to Consider When Choosing Braided Brake Lines

When choosing braided brake lines, I look at their material durability and overall quality to guarantee safety and longevity. I also check if they’re compatible with my vehicle and have the right fittings for a secure connection. Finally, I consider how resistant they are to environmental factors and how easy they are to install and maintain.

Material Durability and Quality

Choosing braided brake lines with high material durability is essential for maintaining peak braking performance and safety. High-quality lines typically feature a stainless steel braided exterior, which resists abrasion, corrosion, and environmental damage, ensuring longevity. The inner lining, often made from PTFE, offers excellent chemical resistance and remains reliable under high-pressure and high-temperature conditions. Durability depends heavily on the thickness of the braiding and the quality of the PTFE lining; thicker braiding and premium linings generally last longer. Additionally, the fittings and crimping process are vital, preventing leaks and guaranteeing secure connections over time. Materials used in top-tier braided brake lines are designed to withstand repeated flexing, bending, and exposure to road debris, mud, and off-road elements, ensuring consistent performance and long-term reliability.

Compatibility With Vehicle

To guarantee your braided brake lines fit and perform correctly, you need to verify their compatibility with your vehicle’s specific make, model, and year. Start by checking the fitting type and size, such as 3 AN or -3, and confirm bolt sizes like 10mm or 1/4 inch to ensure proper connections. It’s also essential to match the line length to the distance between connection points on your vehicle. Additionally, verify that the brake lines are designed for your vehicle’s specific application—whether front, rear, or clutch—to prevent mismatches. Finally, review the manufacturer’s specifications to guarantee the lines are compatible with your existing brake components and any modifications or lifts. Proper compatibility guarantees peak performance and safety.

Fitting and Connection Types

Selecting the right fitting and connection type is essential for ensuring your braided brake lines work effectively and safely. AN fittings are common, featuring standardized threads and often a swivel or flared end to secure the hose. They’re versatile and suitable for many high-performance setups. Compression fittings use a metal sleeve to compress around the hose and thread directly into a fitting, creating a tight seal without needing flaring—ideal for simpler installations. Banjo fittings connect via a hollow bolt with a washer, making them compact and leak-proof, especially at calipers or master cylinders. It’s vital to match your brake line’s connection type with your vehicle’s existing ports. A proper fit guarantees a secure, leak-free, and high-pressure-capable brake system, ensuring safety and reliable performance.

Resistance to Environmental Factors

When evaluating braided brake lines, their resistance to environmental factors is a key consideration for durability and performance. Stainless steel braiding offers excellent resistance to corrosion and rust, even in harsh conditions, ensuring longevity. The braided exterior acts as a shield against debris, mud, rocks, and off-road contaminants that can damage rubber hoses. Inside, PTFE lining provides chemical resistance to brake fluids, oils, and other automotive fluids, maintaining consistent performance across various environments. The stainless steel braid also prevents expansion and swelling under high pressure, preserving a firm brake pedal feel in extreme weather. Properly designed braided lines withstand temperature swings caused by heavy braking or off-road use, avoiding deterioration. This resilience makes them a reliable choice for any driving condition.

Installation and Maintenance Ease

Choosing braided brake lines that feature quick-connect fittings and clear installation instructions can considerably streamline the setup process, saving both time and effort. Lines made from flexible materials like PTFE lining and braided stainless steel are easier to bend and position without kinking or damage, making installation smoother. Properly labeled lines and pre-assembled fittings help prevent errors, ensuring correct orientation and secure connections from the start. High-quality fittings with corrosion-resistant coatings reduce the need for frequent maintenance or replacements. Regular inspections for leaks, wear, and corrosion are straightforward with these lines, especially when combined with simple procedures for tightening fittings. Overall, ease of installation and maintenance is a key factor to contemplate for a safer, hassle-free upgrade.

Frequently Asked Questions

How Do Braided Brake Lines Improve Braking Performance?

Braided brake lines improve braking performance by providing more consistent pressure and reducing expansion under force. I’ve noticed that my stops feel firmer and more responsive because these lines resist flexing better than rubber ones. They also help eliminate sponginess in the brake pedal, giving me greater control. Overall, I trust braided lines to deliver more reliable braking, especially during intense or repeated stops, making my driving safer and more confident.

Are Braided Brake Lines Compatible With All Vehicle Types?

Braided brake lines are compatible with most vehicle types, including cars, trucks, and motorcycles. I always double-check the specific make and model before installing, since fittings and sizes can vary. Generally, they’re a straightforward upgrade that fits well with standard brake systems. Just make certain you select lines designed for your vehicle’s specifications, and if unsure, consulting a professional can help guarantee proper fit and safety.

What Maintenance Is Required for Braided Brake Lines?

Did you know that proper maintenance can extend the lifespan of braided brake lines by up to 30%? I regularly inspect my lines for cracks, leaks, or wear and make certain they’re clean and free from debris. I also check the fittings and connections for tightness and replace them if I notice any damage. Keeping an eye on brake fluid levels and replacing fluid as recommended helps maintain ideal performance and safety.

How Do I Identify Quality Braided Brake Lines?

To identify quality braided brake lines, I look for stainless steel braiding that’s tightly woven and resistant to fraying. I also check for high-quality rubber or Teflon inner hoses that resist swelling and heat. Good fittings should be corrosion-resistant, and the lines should come with clear certifications or warranties. Overall, I choose brands with positive reviews and proven durability, ensuring my safety and peak braking performance.

Can Braided Brake Lines Be Installed DIY or Require Professional Help?

Installing braided brake lines is like assembling a puzzle—you can do it yourself if you’re comfortable with car maintenance. I’ve done it myself a few times, but it’s not for everyone. If you’re handy with tools and follow instructions carefully, you can probably handle it. However, if you’re unsure or new to brake work, I recommend getting a professional to guarantee everything’s installed safely and correctly.

Conclusion

Choosing the right braided brake lines is like giving your vehicle a suit of armor—enhancing safety and performance every time you hit the brakes. With so many options out there, you’ll want to pick lines that fit your needs perfectly. Remember, quality lines are the backbone of reliable stopping power. Invest wisely, and you’ll have peace of mind knowing your brakes are ready to perform when you need them most.